What Is LAMINAX™?

LAMINAX™ is manufactured from metal foil and strips. These materials are enclosed within insulating film through a proprietary laminating process. Unlike traditional adhesive-based solutions, LAMINAX™ boasts a bond produced without the need for adhesive. This results in thinner laminates with exceptional dielectric strength.

The Versatility of LAMINAX Products

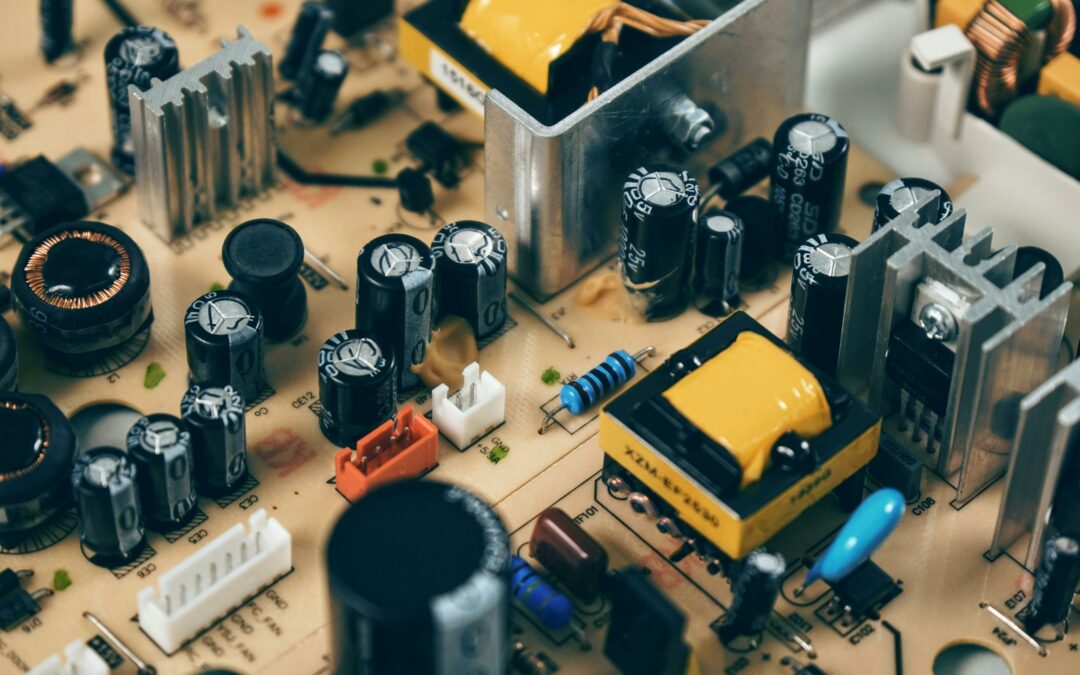

RFI/EMI Shielding

Electromagnetic interference (EMI) and radiofrequency interference (RFI) pose significant challenges to electronics. LAMINAX™ is a reliable solution. Its shielding capabilities make it an ideal choice for protecting sensitive electronic components from external interference, ensuring optimal performance and reliability.

Winding Conductors

LAMINAX™ is also a powerhouse when it comes to winding conductors. Whether it’s replacing interleaved winding of individual materials or enhancing the efficiency of foil coils, LAMINAX™ offers unparalleled performance and flexibility.

Benefits of LAMINAX™ Products

Sustainability is a top priority in modern manufacturing, and LAMINAX™ meets that standard. It is RoHS-compliant, halogen-free, and aligns perfectly with the transformer industry’s green initiatives, ensuring a cleaner, greener future without compromising performance.

Exploring the LAMINAX Family

LAMINAX™ lineup boasts a plethora of options tailored to specific needs:

- B-Series: Revolutionizing the winding process by bonding insulating film on one side of the foil, the B-Series eliminates the need for interleaved winding, streamlining manufacturing processes while enhancing efficiency.

- BM-Series: By bonding multiple parallel foil or strip conductors onto a common backing film, the BM-Series opens up new possibilities in transformer design, offering unmatched versatility and performance.

- C-Series: Partially enclosing metal foil or strip in insulating film, the C-Series provides a range of bonding configurations, making it a go-to choice for shields in toroidal transformers and winding conductors in foil coils.

- EB-Series and EC-Series: These series replace interleaved winding with various bonding configurations, providing a balance of performance and cost-effectiveness to meet a variety of application requirements.

- J-Series: The J-Series bonds and folds plain film around the metal foil, sealing it with a strip of bonding tape. This innovative design ensures easy removal when required, streamlining maintenance and repair processes.

Meeting Diverse Needs

LAMINAX™ RFI/EMI shielding tape and flat winding conductors cater to a range of industries, such as:

- Electronics and Telecommunications: These products ensure optimal performance and reliability of devices such as smartphones, routers, computers, and telecommunication equipment.

- Automotive: Shielding tape and conductors are extensively used in automotive electronics to enhance electromagnetic compatibility (EMC) and reduce the risk of malfunctions.

- Aerospace and Aviation: Shielding tape and conductors are used in avionics, navigation systems, communication equipment, and electronic control units to safeguard against electromagnetic interference from external sources such as radar systems and communication networks.

- Medical Devices: Shielding tape and conductors are used in devices such as MRI machines, pacemakers, defibrillators, and monitoring equipment to mitigate the risk of electromagnetic interference.

- Renewable Energy: RFI/EMI helps ensure the reliable operation of solar inverters, wind turbines, and energy storage systems.

At Bridgeport Magnetics, we offer a range of LAMINAX™ configurations to suit your needs. Contact us today. You can also call us at (203) 954-0050 or (800) 836-5920 or send us an email at sales@bridgeportmagnetics.com.