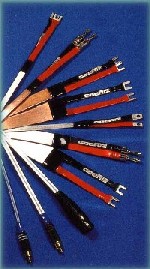

MI/AG Speaker Cables

Overview

But developing such a wire is a different proposition. Many audio companies do not even manufacture their own wire; packaging and marketing the products of others instead. As a primary maker of high-tech laminated conductors for industrial electronics applications,

Bridgeport Magnetics Group was uniquely suited to transform the promising Goertz design into reality. Using the dielectrics Polyester Terapthalate and Teflon applied around each solid rectangular conductor, we achieved an extraordinarily thin profile between the two stacked wires. To provide maximum protection while maintaining thinness, the cable sandwich is then sheathed in tough, high grade polymer.

The result is a wire with a characteristic impedance that closely matches the impedance of loudspeakers. Bridgeport Magnetics Group’s Goertz MI wire presents 2 to 4 ohms characteristic impedance as opposed to the 50 to 200 ohms presented by even the most expensive speaker cables. This correct electrical matching results in improved stereo imaging, better clarity, less high-frequency roll off and better low frequency definition.

The patented Goertz MI cable, invented by Ole Goertz, a Danish electronics and audio engineer, eliminates distortion between amplifier and loudspeakers. Patented in 20 countries, Goertz wire is flat by design. It’s form follows function, in the best design tradition. We set out to create an electrically correct pathway between amplifier and loudspeaker, which required replacing typical cable psuedo-science with solid physics. Research showed that the perfectly flat shape, with minimum space between conductors, was the best way to achieve this.

But developing such a wire is a different proposition. Many audio companies do not even manufacture their own wire; packaging and marketing the products of others instead. As a primary maker of high-tech laminated conductors for industrial electronics applications,

Bridgeport Magnetics Group was uniquely suited to transform the promising Goertz design into reality. Using the dielectrics Polyester Terapthalate and Teflon applied around each solid rectangular conductor, we achieved an extraordinarily thin profile between the two stacked wires. To provide maximum protection while maintaining thinness, the cable sandwich is then sheathed in tough, high grade polymer.

The result is a wire with a characteristic impedance that closely matches the impedance of loudspeakers. Bridgeport Magnetics Group’s Goertz MI wire presents 2 to 4 ohms characteristic impedance as opposed to the 50 to 200 ohms presented by even the most expensive speaker cables. This correct electrical matching results in improved stereo imaging, better clarity, less high-frequency roll off and better low frequency definition.

Goertz Improves all Frequency Ranges:

LOW . . . MIDRANGE . . . HIGH

The degree of distortion along a loudspeaker cable depends on its resistance ( R ), inductance ( L ) and capacitance ( C ). Resistance is dependent on length and conductor cross section. A low resistance provides superior damping between the amplifier and the speaker diaphragm, governing its ability to convey a true, powerful bass and lower mid-range. A high cable inductance causes loss of signal strength towards the high end of the audible range (roll-off). It also causes frequency dependent phase-shift which disturbs true stereo imaging. The square root of the ratio L/C is termed Characteristic Impedance, and is a quality inherent in a cable, dependent on its geometry and materials, but not dependent on its length.

Goertz Virtually Eliminates Mismatch

The characteristic impedance of the Goertz MI cables in the order of 2 to 4 ohms closely matches the impedance of loudspeakers. Almost all other speaker cables have characteristic impedance ranging from 50 to 200 ohms, a mismatch which causes distortion due to signal reflections. Impedance matching primarily improves the clarity of the highs and upper mid-range, but many users have also experienced improvements in the lower mid-range. The cause seems to be that signal reflections caused by impedance mismatch enter the feedback loop of many amplifiers and disturb their ability to reproduce faithfully even lower frequency signals.

Thick on Benefits, Thin as a Penny

The low inductance and characteristic impedance of Goertz cables are due to their flat construction and the nature of their insulation and jacketing material. The configuration places the heavy, solid conductors only 0.003 inches apart. The cables are 0.4 or 0.8 inches wide, and only 0.04 inches thick. As thin as a penny.

Perfect for Home Theater

Goertz MI speaker cable and interconnects are perfect for home theater applications. Due to the low inductance characteristics, Goertz audio products are ideal for long runs. No more positioning your equipment based on the limitations of your cable system. Dolby Digital home theater design requires full range audio frequencies be sent to rear speakers; Goertz cable allows extreme accuracy at any length. The space ratio, the relationship between conductor cross section, is about 50% in Goertz MI cables versus 5-20% in most other speaker cables. In other words, Goertz cables pack heavy conductor cross sections into an extremely slim package yielding greatly improved highs and mid-range, plus a truly powerful bass. Thanks to the flat construction and extreme compactness, they can be drawn anywhere and routed under thin carpets and wallpaper. If desired, paint with oil or water based paint.

What makes them so special?

The Proof: Oscilloscope readings comparing the performance

of a Goertz cable with conventional designs.

Specifications

| Goertz Cable | Conductors/ | Resistance/ | Dielectric Material/ |

Goertz MI 1: | High Purity | 0.0044 ohms/ft | Polyester Terepthalate/ |

Goertz MI 2: | High Purity | 0.0022 ohms/ft | Teflon/ Polyester Terepthalate/ |

Goertz MI 3: | High Purity | 0.0011 ohms/ft | Teflon/ Polyester Terepthalate/ |

Goertz AG 1: | High Purity | 0.0034 ohms/ft | Polyester Terepthalate/ |

Goertz AG 2: | High Purity | 0.0017 ohms/ft | Teflon/ Polyester Terepthalate/ |

Goertz AG 3: | High Purity | 0.00098 ohms/ft | Teflon/ Polyester Terepthalate/ |

Temperature Rating: | -40°F to +270°F | Maximum Operating Voltage: 300 Volts | ||

| Any length terminated and 25/150/500 foot bulk spools | ||

Reach Us

Contact Us for Information and Sales

6 Waterview Drive, Shelton, CT 06484